- Deep groove ball bearing

- Angular contact ball bearing

- Needle roller bearing

- Self-aligning ball bearing

- Spherical roller bearing

- Cylindrical roller bearing

- Tapered roller bearing

- Thrust bearing

- Track roller

- Insert bearing

- Bearing block

- Joint bearing

- Linear bearing

- Combined bearing

- Crossed roller bearing

- Rotary table bearing YRT

- Automobile bearing

- Agricultural machinery bearing

Whatsapp:+86 15261589113

Skype:christina.ji4

Email:christina.ji@vip.188.com

38

[ Shanghai Oupan Bearing Co.,LTD clicks: ]

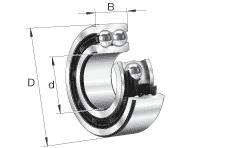

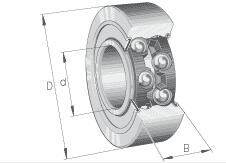

Double row angular contact ball bearings are units with solid inner and outer rings and ball and cage assemblies with polyamide or sheet steel cages. Their construction is similar to a pair of single row angular contact ball bearings in an O arrangement but they are narrower to a certain extent.

The bearings are available in open and sealed designs. Due to the manufacturing processes used, open bearings can have turned recesses in the outer ring for seals or shields. Sealed bearings are maintenance-free and therefore allow particularly economical bearing arrangements.

Due to the raceway geometry and the two rows of balls, the bearing can support forces in both radial and axial directions. They are therefore particularly suitable for use in pumps and agricultural machinery. Furthermore, double row angular contact ball bearings are used in applications including conveying equipment, packaging equipment, elevators and compressors.

The angular adjustment facility of angular contact ball bearings is very limited. The adjustment angle should not exceed

Lower noise levels:

Due to the higher ball quality, improved raceway surfaces and the more precise dimensional and running tolerances to

Reduced friction:

Lower friction leads to reduced heat generation and thus a longer grease operating life. As a result, higher speeds or an extended operating life of the bearing can be achieved. In addition, this increases the energy efficiency of the application.

Improved sealing:

The

Higher cost-effectiveness:

Overall, these measures lead to greater economic benefit for the user. Double row angular contact ball bearings of X-life quality offer a longer operating life, especially in use under axial load conditions. The maintenance intervals in the specific applications can thus be extended. Due to the reduced friction, savings on energy consumption and operating costs can be achieved.

Radial and axial load carrying capacity:

Double row angular contact ball bearings can support axial loads in both directions and high radial loads. They are particularly suitable for bearing arrangements where rigid axial guidance is required.

The axial load carrying capacity is dependent on the contact angle; i.e. the larger the angle

Without filling slot:

Bearings of

Sealing:

Series with the suffix

Both

Lubrication:

Sealed bearings are greased with a high quality grease and are lubricated for life. Open bearings are preserved using oil. In addition to the standard grease, special greases are also available by agreement for particular operating conditions.

Operating temperature:

Open bearings are suitable, depending on their outside diameter, for different operating temperature ranges. Bearings are available by agreement for temperatures up to

|

Outside diameter |

Operating temperature |

|

mm |

℃ |

|

≧ |

|

|

> |

|

Bearings with cages made from glass fibre reinforced polyamide are suitable for operating temperatures up to

Bearings with the suffix

Suffix:

BD Modified internal construction, contact angle

TVH Solid polyamide snap cage, ball-guided

2HRS Lip seals on both sides

2Z Gap seals on both sides

C2 Axial internal clearance C2

C3 Axial internal clearance C3

C4 Axial internal clearance C4

S0 Dimensional stabilisation

S1 Dimensional stabilisation

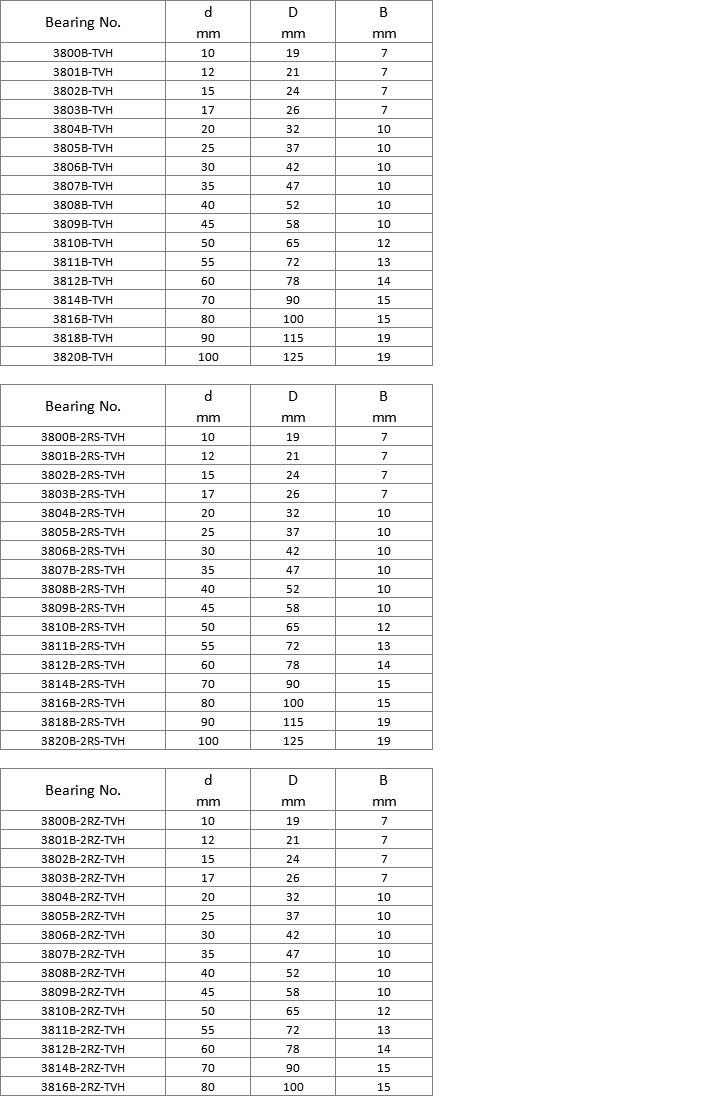

Angular contact ball bearings 38..-B, double row, contact angle α = 25°

Angular contact ball bearings 38..-B-2RS, double row design, lip seals on both sides, contact angle α = 25°

Angular contact ball bearings 38..-B-2RZ, double row design, non-contact radial seals on both sides, contact angle α = 25°